Webinar Registration: The P2G Advantage

Webinar Registration: The P2G Advantage LEARN MORE

Who We Are

We’re supply chain people too. That experience led us to reimagine warehouse fulfillment with our intelligent, AI-driven, enterprise-grade robotics platform. Our purpose-built AMRs transform workflows, dramatically boosting warehouse productivity, operational efficiency, and workplace safety.

Our award-winning solution improves productivity 2-3X while cutting labor costs in half.

Any Environment

Seamless Deployment

Optimized Productivity

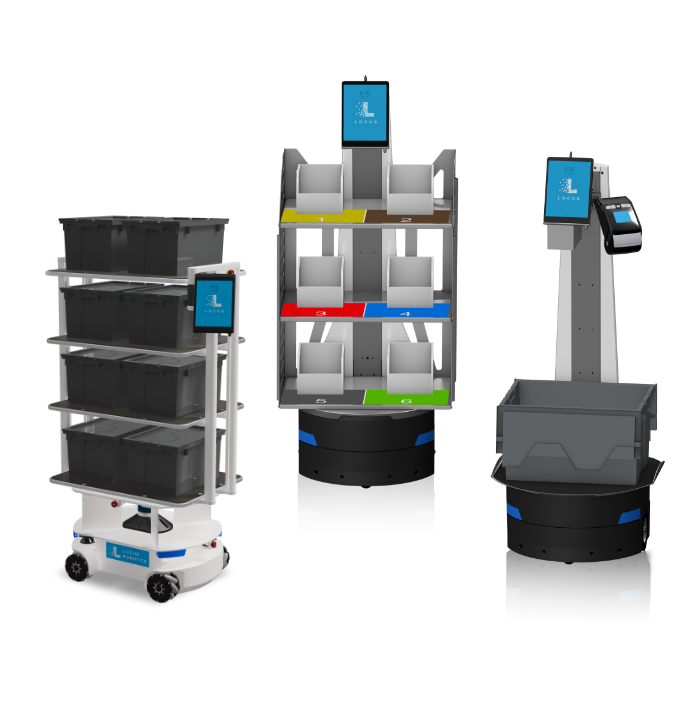

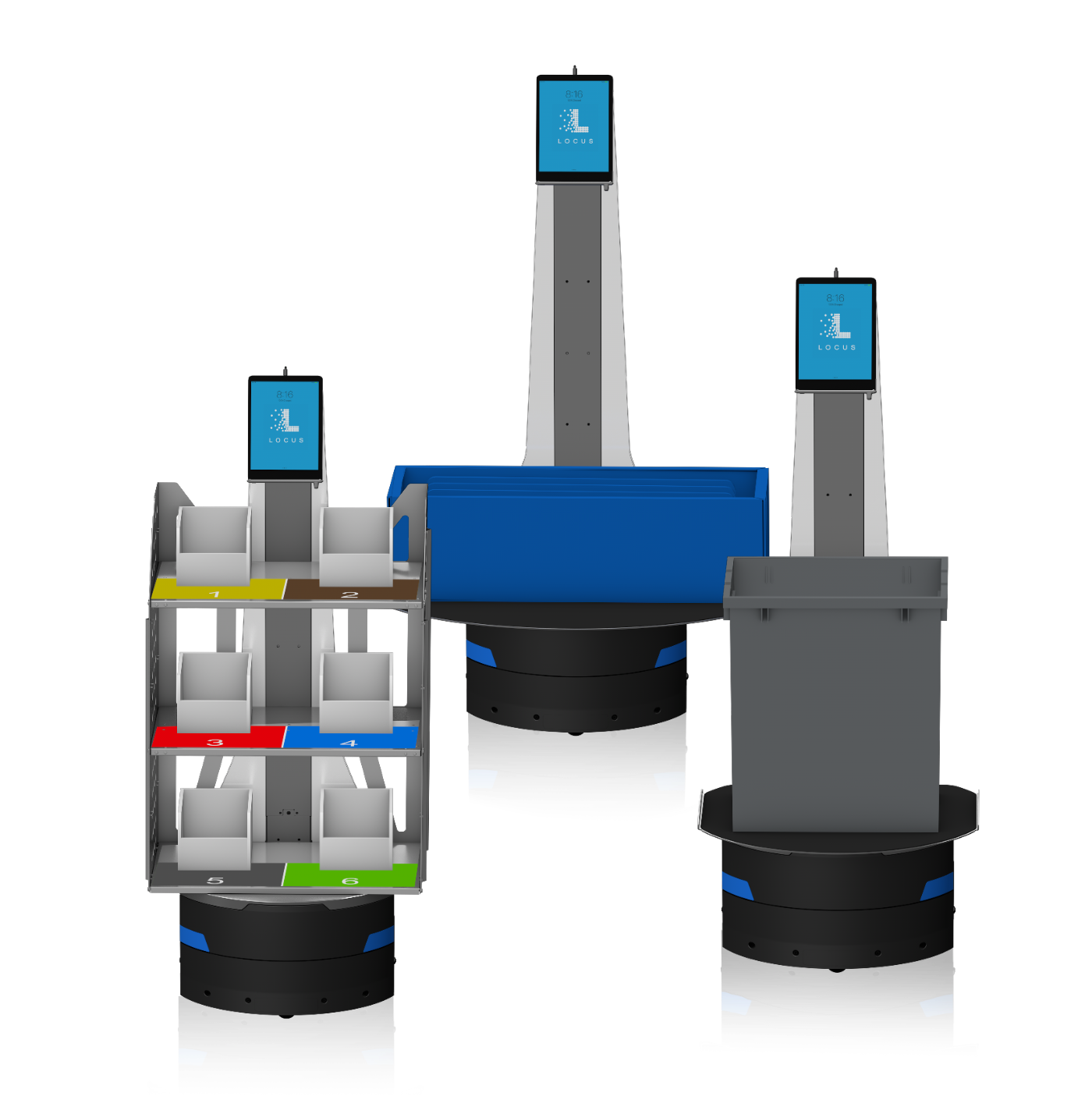

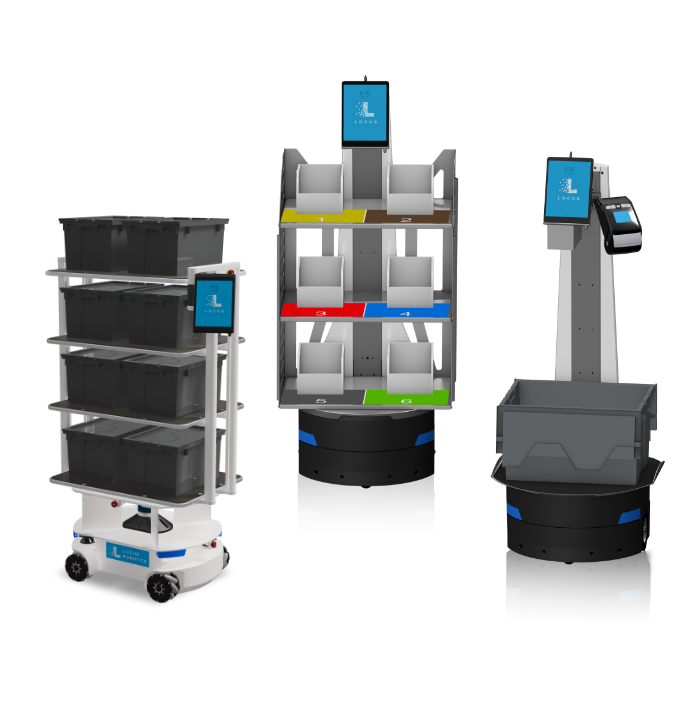

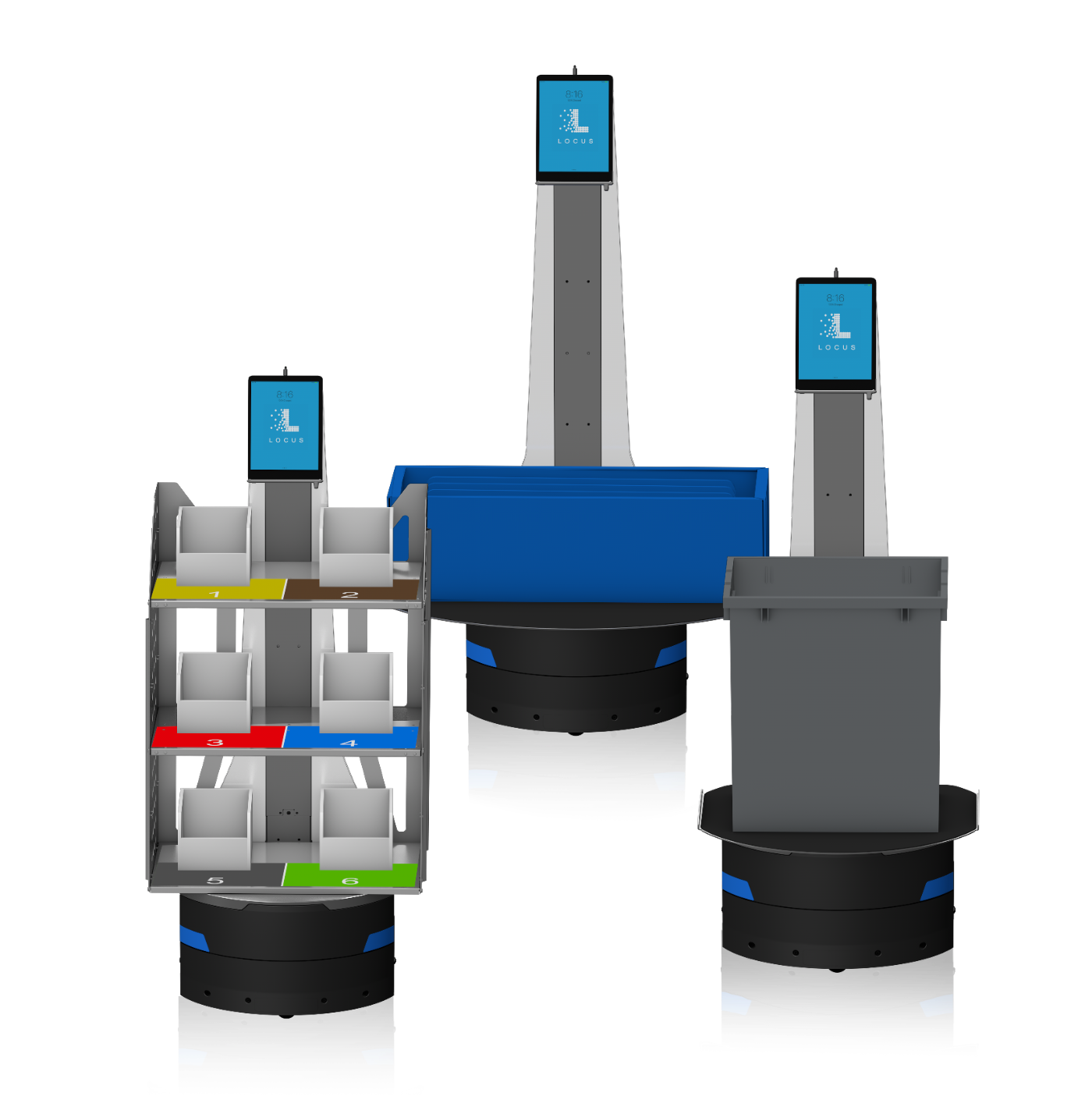

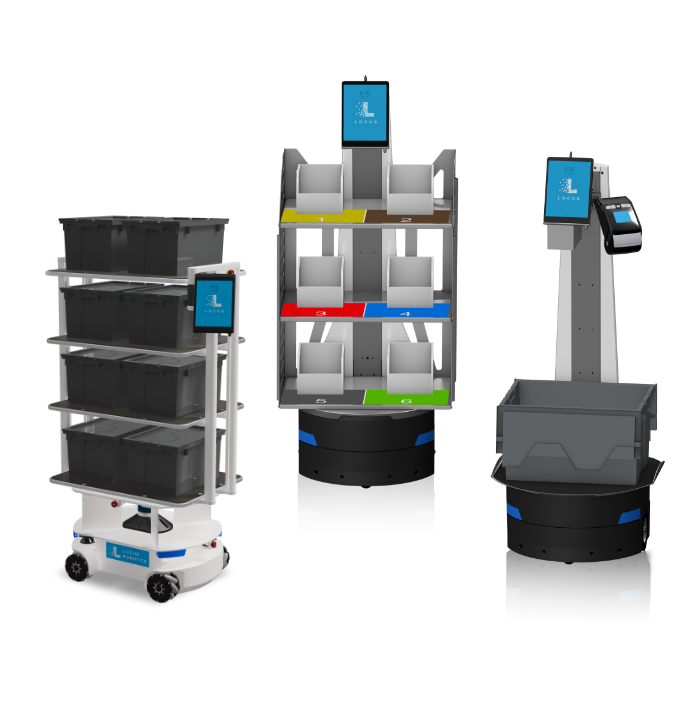

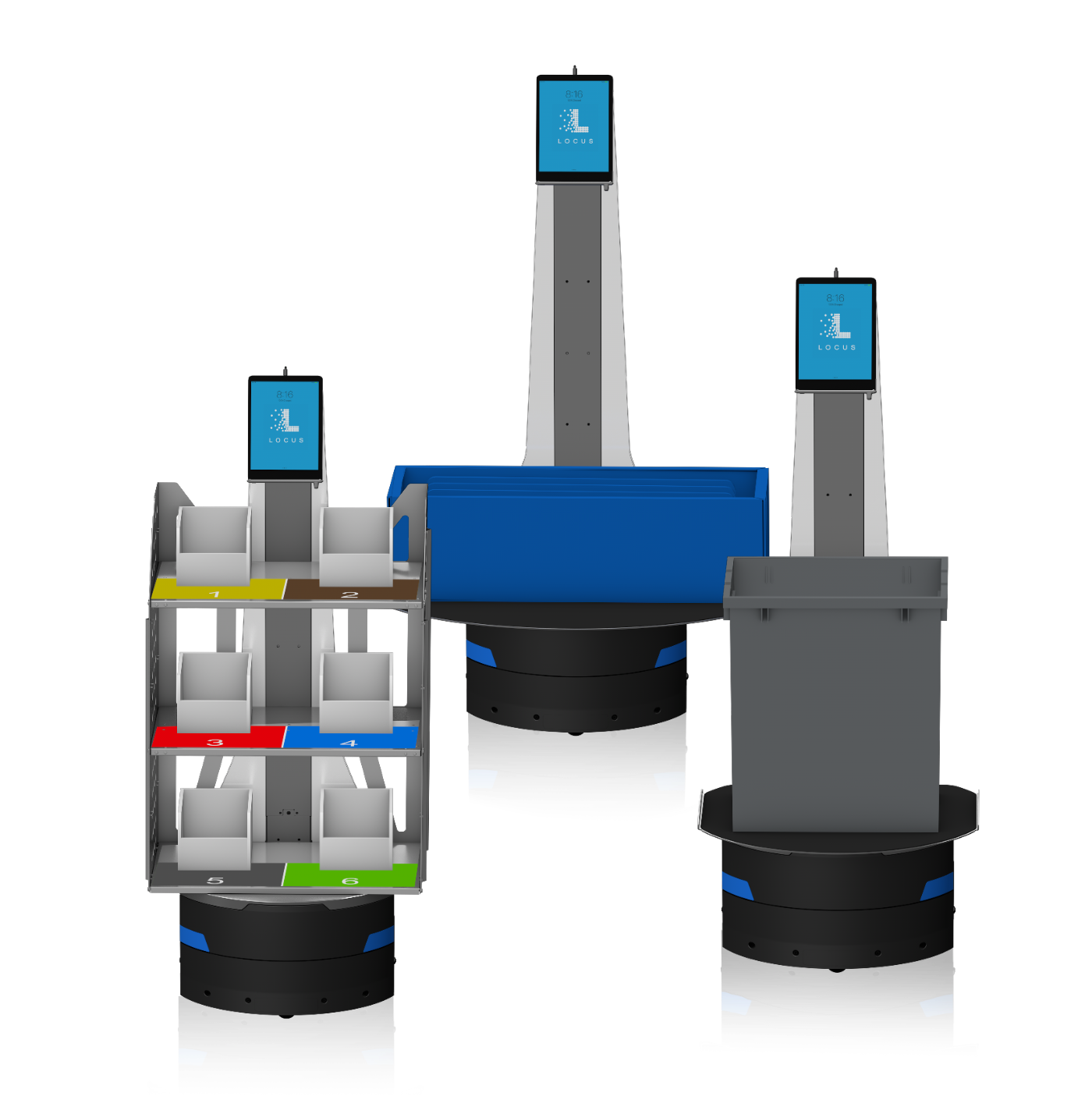

Versatility Matters

Any payload. Any process. Any use case. Whether you serve one industry or a dozen, Locus has the right bot for the job so you can Move What Matters.

Picking

Actively direct workers to their next discrete, case, or batch pick location

LEARN MOREPutaway

Integrate warehouse putaway with true task interleaving

LEARN MOREPoint-to-Point Transport

Flexible robotic transport system

LEARN MOREMezzanine Management

Optimize multi-level warehouse fulfillment

LEARN MOREIntelligent, AI-driven Enterprise Warehouse Automation

Any payload. Any process. Any use case. Whether you serve one industry or a dozen, Locus has the right bot for the job so you can Move What Matters.

LocusOne

We have a deep warehouse heritage and in-depth, first-hand experience with the development and evolution of warehouse automation. Our founders were early adopters of robotics technology to improve warehouse productivity.

LEARN MORE

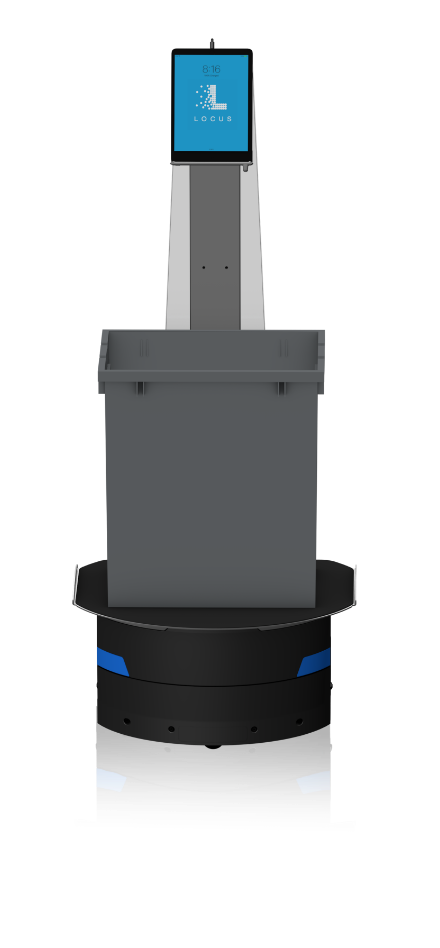

Locus Origin

Engineered for maximum warehouse efficiency, Locus Origin delivers optimal productivity with agile maneuverability, incorporating the latest navigation and vision system technologies. Works safely and easily alongside associates in dynamic environments.

LEARN MORE

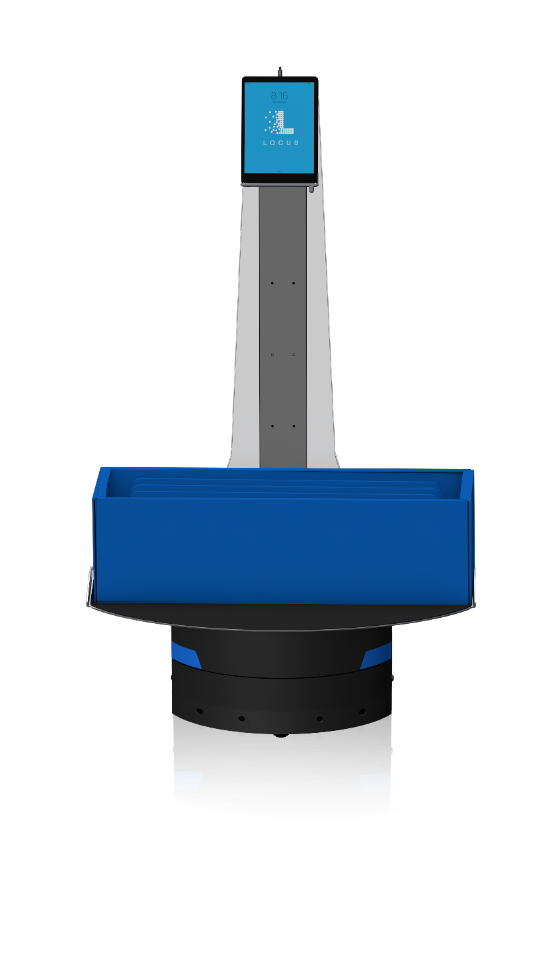

Locus Vector

The AMR with the flexibility for a wide range of roles from fulfillment to transport to putaway. Locus Vector features an industrial strength chassis, omnidirectional mobility, and compact design for use in any environment.

LEARN MORE

Customers

Metrics that Matter

6-8

Months to ROI

2-3x

Productivity Gains

50%

Faster Cycle Time

4-6

Weeks to Go-Live

300+

Facilities Contracted

18

Countries

13k+

Bots in the Field

700+

Bots at One Site

Featured Resources

Ready To Get Started?

Let’s talk about your operation and how Locus can help you achieve your goals, today and into the future.